Introduction to 3D Printing

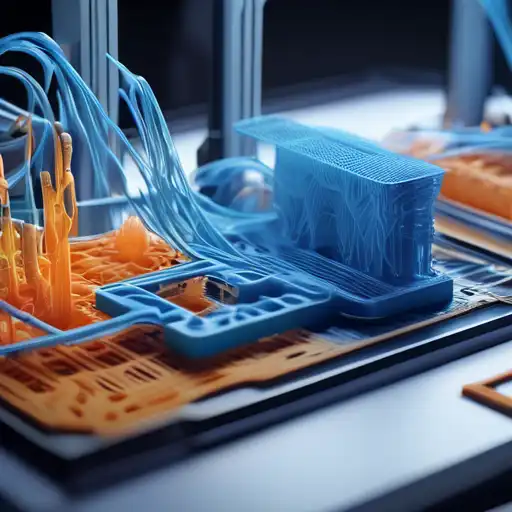

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This innovative technology builds objects layer by layer, offering unparalleled flexibility in design and manufacturing. From prototyping to production, 3D printing is revolutionizing industries worldwide.

How 3D Printing Works

The process begins with a digital 3D model, which is sliced into thin layers by specialized software. The 3D printer then builds the object by depositing material layer by layer until the entire object is formed. Materials used can range from plastics and metals to ceramics and even biological materials.

Applications of 3D Printing

3D printing has found applications in various fields, including:

- Healthcare: Custom prosthetics and implants

- Automotive: Rapid prototyping and parts manufacturing

- Aerospace: Lightweight components for aircraft

- Fashion: Custom jewelry and clothing

This versatility makes 3D printing a key player in the future of manufacturing.

Benefits of 3D Printing

3D printing offers numerous advantages over traditional manufacturing methods, such as:

- Reduced waste: Only the necessary material is used

- Customization: Easy to create personalized products

- Speed: Faster from design to production

- Complexity: Ability to produce complex geometries

These benefits are driving the adoption of 3D printing across industries.

Challenges and Future Directions

Despite its potential, 3D printing faces challenges like material limitations and high costs for certain applications. However, ongoing research and development are addressing these issues, paving the way for broader adoption. The future of 3D printing includes advancements in speed, materials, and sustainability, further solidifying its role in creating the future layer by layer.

For more insights into innovative technologies, explore our technology section.